Checking Out The Differences Between Tunnel Pasteurizers And Batch Pasteurizers: Which Is The Preferred Method?

When determining between Tunnel pasteurizers and batch pasteurizers, you might ask yourself which alternative matches your manufacturing requires best. https://www.outsideonline.com/food/whats-best-way-haul-beer-and-other-beverages-backcountry/ like manufacturing quantity, operating costs, and item quality all entered play when making this crucial option. Understanding the unique advantages and restrictions of each system can help you make an enlightened choice that straightens with your company goals and high quality standards. Keep tuned to find key insights that will certainly guide you in selecting the optimal pasteurization solution for your certain needs.

## Efficiency and Throughput

When comparing Tunnel pasteurizers to batch pasteurizers in regards to effectiveness and throughput, the previous typically outshines the last in continuous processing abilities. Tunnel pasteurizers are made for continual processing, enabling a continuous circulation of products via the system. This setup allows higher throughput prices contrasted to batch pasteurizers, which operate in cycles with stops between each batch.

The continual circulation in Tunnel pasteurizers results in a more effective handling method, lowering bottlenecks and making the most of manufacturing result.

Furthermore, Tunnel pasteurizers supply far better temperature level control throughout the entire process. The regular temperature level levels kept in Tunnel pasteurizers ensure consistent pasteurization of products, enhancing performance and high quality.

In contrast, batch pasteurizers might experience temperature level changes in between batches, potentially affecting the total performance of the pasteurization process.

## Expense Evaluation

To better examine the usefulness of Tunnel pasteurizers versus batch pasteurizers, a vital element to think about is the cost analysis. Tunnel pasteurizers typically have a greater upfront expense because of their automated and constant operation, but they offer significant savings in labor costs over time. On the other hand, batch pasteurizers have a reduced preliminary financial investment however may call for even more manual labor, enhancing operational costs in the long run.

When assessing the cost-effectiveness of each alternative, it's necessary to take into consideration not only the purchase rate however also continuous expenditures like energy usage, maintenance, and labor. Tunnel pasteurizers have a tendency to be extra energy-efficient considering that they run constantly and make use of heat recovery systems. batch pasteurizers, while simpler in design, might eat a lot more power during each batch handling cycle.

Eventually, the choice in between Tunnel and batch pasteurizers will certainly depend upon your manufacturing volume, budget restrictions, and lasting functional goals. Carrying out a comprehensive expense evaluation considering both immediate and lasting costs will certainly aid you determine the most affordable remedy for your certain needs.

## Product Quality and Life Span

For ideal item top quality and prolonged service life, the option in between Tunnel pasteurizers and batch pasteurizers plays an essential function in your manufacturing procedure.

Tunnel pasteurizers are understood for their capability to give constant and consistent warm distribution throughout the product, guaranteeing that all containers are sterilized successfully. This harmony assists maintain the quality of your products by decreasing the risk of under or over-pasteurization.

On the other hand, batch pasteurizers provide even more adaptability in processing smaller sized amounts of items with differing dishes or ingredients. While this versatility can be advantageous in certain situations, it may additionally result in inconsistencies in pasteurization levels, possibly affecting product quality and life span.

When it comes to shelf life, the precision and control offered by Tunnel pasteurizers can aid prolong the durability of your items by making sure that harmful microorganisms are properly eliminated. This can cause a much longer shelf life for your items, inevitably profiting your service and consumers. Take into consideration the particular demands of your products and production process to identify which pasteurization approach aligns ideal with your goals for item quality and life span.

## Final thought

In conclusion, when deciding in between Tunnel pasteurizers and batch pasteurizers, it is clear that Tunnel pasteurizers use exceptional effectiveness, throughput, cost-effectiveness, and product top quality. With their continuous handling abilities, better temperature level control, and prolonged service life benefits, Tunnel pasteurizers are the recommended option for several food and beverage manufacturers. Make the switch to Tunnel pasteurizers for enhanced results in your manufacturing process.

Understanding The Benefits Of Batch Pasteurization: A Thorough Source For Food Manufacturers

When it comes to boosting your food production procedures, batch pasteurizers offer a wide range of benefits worth thinking about. From making sure the security and high quality of your items to enhancing efficiency and consistency, these machines hold the trick to a much more efficient operation. Yet that's simply scratching the surface. By exploring the extensive guide given, you'll reveal a wealth of info that can reinvent the means you approach food manufacturing.

## Improved Product Security and Quality

When using batch pasteurizers in your food producing process, you can anticipate a significant enhancement in item safety and security and high quality. By making use of batch pasteurizers, you make sure that damaging pathogens are efficiently eliminated from your products, decreasing the danger of foodborne ailments.

The exact temperature level control and consistent warmth circulation supplied by these pasteurizers assure that your items are safely pasteurized without endangering their high quality or taste.

Additionally, batch pasteurizers assist in extending the service life of your products by eliminating spoilage-causing microorganisms, mold and mildews, and yeasts. This implies that your food products will certainly maintain their quality for longer durations, minimizing waste and enhancing client fulfillment.

With enhanced item security and high quality, you can with confidence satisfy regulatory criteria and customer expectations, developing a solid reputation for your brand name.

“From Cosmetics to Pharmaceuticals: How Tunnel and Batch Pasteurizers Are Revolutionizing Product Safety”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) October 8, 2024

Article Release for Brewmasters

Article: https://t.co/MBbegEueSw

PRO Engineering / Manufacturing Inc.

414-362-1500

sales@prowm.com

https://t.co/GkQF8BPrG3

Including batch pasteurizers right into your food producing procedure is an aggressive action that shows your dedication to supplying safe, high-grade items to your clients. By investing in this modern technology, you aren't just safeguarding public health but additionally enhancing the general value of your food products.

## Streamlined Manufacturing Processes

Occasionally, enhancing your food manufacturing procedure with batch pasteurizers can cause structured production procedures. By integrating batch pasteurizers right into your procedures, you can maximize the home heating and cooling cycles, resulting in a lot more reliable production timelines. With accurate temperature level control and automated procedures, batch pasteurizers help in reducing manual work requirements and decrease the danger of human error during production.

In addition, batch pasteurizers permit regular and repeatable results, making sure that each batch meets the very same high quality standards. This consistency gets rid of the demand for comprehensive hands-on surveillance and adjustments, conserving time and sources in the future.

Streamlining your manufacturing processes with batch pasteurizers can additionally result in boosted total efficiency, permitting you to concentrate on other facets of your organization.

In addition, the streamlined manufacturing procedures enabled by batch pasteurizers can help you satisfy limited deadlines and respond promptly to variations popular. By boosting effectiveness and decreasing manufacturing bottlenecks, batch pasteurizers add to an extra active and responsive manufacturing operation.

## Extended Service Life and Consistency

Boost the high quality and long life of your food products with the execution of batch pasteurizers for extensive shelf life and consistency. By using batch pasteurizers, you can substantially lengthen the life span of your food products. The precise temperature level control and consistent home heating offered by batch pasteurizers guarantee that hazardous microorganisms are removed, expanding the freshness of your products.

Uniformity is key in the food industry, and batch pasteurizers provide a dependable method to attain uniform outcomes with each production cycle. By maintaining regular warmth distribution throughout the pasteurization procedure, batch pasteurizers assist you supply items that fulfill the same high standards whenever. This not just boosts client complete satisfaction but likewise develops rely on your brand name.

With batch pasteurizers, you can generate food products with extensive service life while preserving uniformity in high quality. This twin benefit not only enhances the marketability of your items but additionally decreases waste, inevitably adding to a much more reliable and successful operation.

## Verdict

Generally, batch pasteurizers provide food manufacturers a wide range of benefits, including improved item safety and security, quality, and consistency. By streamlining manufacturing processes and extending service life, these makers not just enhance customer satisfaction but additionally enhance marketability and success. Embracing batch pasteurizers can transform food manufacturing operations, offering an one-upmanship in the industry. Make https://www.epicurious.com/expert-advice/beer-cocktail-recipes-low-alcohol-article and experience the countless advantages for yourself.

Factors To Think About When Selecting A Passage Pasteurizer For Your Enterprise

When selecting the ideal Tunnel pasteurizer for your company, you encounter an important choice that can impact your production performance significantly. The procedure involves evaluating different variables like size, capacity, temperature level control, and maintenance needs. It's not just about the initial acquisition; it's also regarding long-term functional costs and assistance. Comprehending the nuances of various Tunnel pasteurizer kinds and their suitability for your details needs is extremely important. Your selection will certainly play a crucial function in making certain the high quality and security of your products while maximizing your production procedures.

## Trick Aspects to Take Into Consideration

When selecting a passage pasteurizer for your business, it's critical to think about a number of key elements that will affect the efficiency and performance of your pasteurization process.

Firstly, examine the size and capability requirements of your production line. Ensure the Tunnel pasteurizer you choose can handle the quantity of items you require to process to stay clear of bottlenecks or delays in manufacturing.

Secondly, consider the heating and cooling capabilities of the pasteurizer. The temperature level control precision is crucial to make sure that your items are sterilized effectively without endangering high quality. Search for a passage pasteurizer that supplies exact temperature level tracking and modification features to fulfill your details pasteurization demands.

Another critical element to take into consideration is the impact and design of the Tunnel pasteurizer. Ensure the tools fits well within your manufacturing facility and can be conveniently integrated right into your existing line without substantial adjustments. Additionally, assess the upkeep demands and the accessibility of technological support for the pasteurizer to make certain smooth operations and very little downtime.

## Kinds Of Tunnel Pasteurizers

To better recognize the varied alternatives available out there, it is necessary to discover the various sorts of Tunnel pasteurizers fit for various production needs and procedures.

One common type is the constant Tunnel pasteurizer, perfect for high-volume production with consistent warmth therapy. If you have differing production speeds, a modular Tunnel pasteurizer could be the most effective fit as it permits flexibility in line configurations.

For smaller sized organizations, a portable Tunnel pasteurizer could be the ideal choice, supplying area efficiency without compromising on pasteurization quality. If your products need certain therapy areas, an adjustable Tunnel pasteurizer might be the most ideal alternative, enabling modification of warm direct exposure degrees.

In addition, Tunnel pasteurizers can be categorized based on heating techniques such as water immersion, steam injection, or hot air, each offering one-of-a-kind benefits relying on the product being processed. Recognizing these types will aid you choose the Tunnel pasteurizer that straightens finest with your organization demands.

## Budgeting and Cost Analysis

Taking into consideration the monetary elements of acquiring a tunnel pasteurizer is a critical step in your business decision-making process. When budgeting for a passage pasteurizer, take into consideration not only the initial purchase cost but additionally continuous costs such as maintenance, power intake, and possible upgrades.

Conduct an extensive cost evaluation to figure out the complete expense of ownership over the life expectancy of the equipment. Look for Tunnel pasteurizers that offer an equilibrium in between ahead of time prices and long-lasting cost savings through power performance and minimized upkeep demands.

https://www.farminglife.com/country-and-farming/belfast-farm-apologises-for-milk-incident-are-there-health-benefits-to-raw-milk-and-who-should-avoid-it-3435471 !3m2!1i1024!2i768!4f13.1!3m3!1m2!1s0x8804fd5afdb23d7f%3A0xb1ad7a83e2f71b22!2sPro%20Engineering%20%2F%20Manufacturing!5e0!3m2!1sen!2sus! https://www.phillyvoice.com/stones-beer-and-beverage-market-reopening-fairmount/ !5m2!1sen!2sus" width="600" height="450" style="border:0;" allowfullscreen="" loading="lazy" referrerpolicy="no-referrer-when-downgrade">

Bear in mind to factor in any type of additional costs such as installment, training, and possible downtime during application. Compare quotes from different vendors and take into consideration working out for a better bargain or exploring financing alternatives to ease the financial problem.

## Verdict

Finally, picking the appropriate Tunnel pasteurizer for your organization needs careful factor to consider of aspects such as size, ability, heating and cooling capabilities, maintenance demands, and technical assistance availability. Examine different kinds of pasteurizers to discover the best suitable for your production requirements and budget plan restrictions. Conduct a detailed price evaluation to identify the overall possession expense, including installation and prospective downtime expenditures. With these factors in mind, you can make an educated choice that will certainly profit your organization in the future.

Protecting Excellence: The Significance Of Tunnel Pasteurizers In Drink Manufacturing

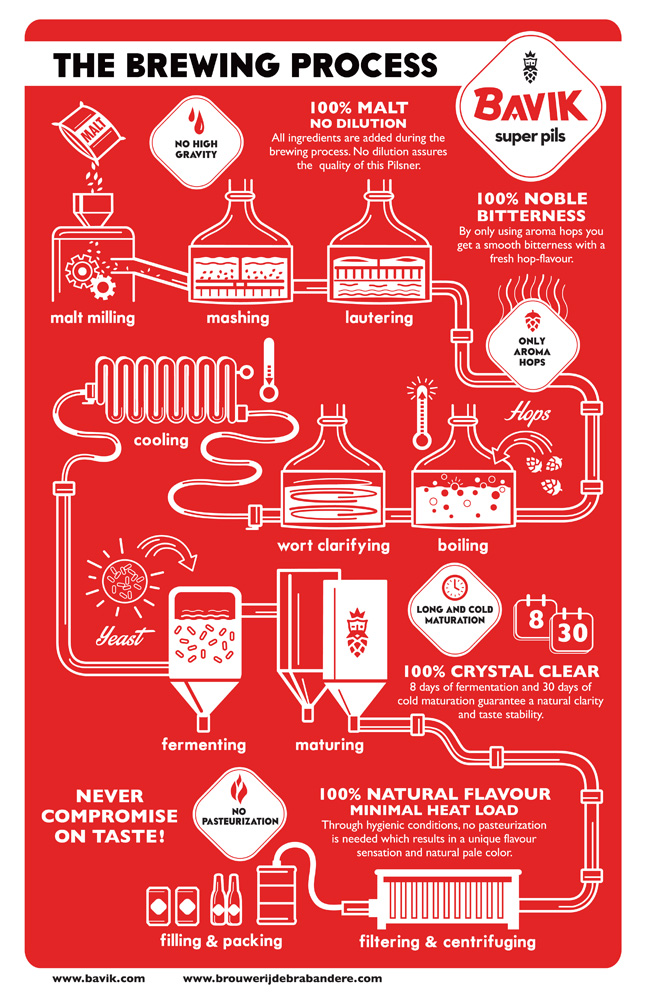

Tunnel pasteurizers are important for getting rid of putridity germs and regulating pathogenic germs in drinks like beer, milk, juice and soft drinks. They warmth and after that cool down the product to eliminate these microbes.

They likewise save power, water and lower carbon dioxide exhausts straightening production with sustainability targets. Selecting a tunnel pasteurization system that's crafted by experienced experts like PRO guarantees accuracy in the timing and temperature degrees used in each stage.

Microbiological Control

The control of bacteria in food and beverages is vital to prevent spoilage, gastrointestinal disorder, and other negative influence on the end product. Microbial contaminations can be caused by pathogenic (i.e., disease-causing) microorganisms or perishing fungis. Approaches for managing microbial contamination can include physical, chemical, or biological techniques. Those that eliminate or inactivate microbes are termed sterilization, sanitation, antisepsis, and sanitization.

Microbial death curves, which illustrate the logarithmic decrease of living microorganisms after direct exposure to a treatment procedure, are crucial tools for identifying the performance of a microbial control technique. The moment it takes for a method to yield a 1-log reduction in the microbial populace is described the decimal decrease worth, or D-value.

"THE ROLE OF PASTEURIZATION IN NON-ALCOHOLIC BEVERAGES: ENSURING TASTE AND SAFETY"

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) August 27, 2024

Article Release for Brewmasters and Beverage Makers

Click for full article: https://t.co/K8ss4FFgYF

PRO Engineering / Manufacturing Inc.

https://t.co/GkQF8BOTQv

To make certain accurate microbial analysis outcomes, it is necessary to keep the sample and the examination system itself without contamination. Utilizing a microbiological incubator that provides an efficient 140 oC decontamination cycle, such as the Thermo Scientific Heratherm Incubator, can aid eliminate cross-contamination between samples and testing tools, hence making sure that the results of any kind of microbial tests stand.

Security

When it concerns keeping your beverage stable, Tunnel pasteurizers can do a lot of job. These machines offer both the bottle or can and its materials a warm treatment-- which assists prolong life span while preserving those specialized active ingredients craft breweries love a lot.

In a common Tunnel pasteurizer, the bundle and fluid are shared via a number of areas that slowly warm and cool the item. Each spray head supplies water at different temperature levels, and the nozzles are placed to optimize protection with a minimum of thermal anxiety.

The timing and temperature of each spray are based on a beverage-specific variety of pasteurization systems (PU) required to kill any microbes in the container. The progressive nature of heating also decreases carbonation loss in low-carbonated drinks.

Safety and security

Tunnel pasteurizers can be made use of to warm deal with a beverage also after it has been loaded right into containers and canisters. This can assist lengthen shelf security for carbonated beverages without sacrificing their fizz.

The procedure functions by gradually heating up a container with sprays of warm water. https://www.brewsnews.com.au/2020/10/21/us-firm-codi-launches-compact-pasteuriser/ is raised in phases up until it gets to the required pasteurization device for the drink and after that kept for the specified period.

When the wanted time and temperature have been accomplished, the beer is cooled down with showers of low-temperature water until it reaches ambient temperature. This guarantees that all bacteria in the beer are killed and it can be safely saved in a secured container.

Tunnel pasteurizers are developed to make certain that the temperature level is equally distributed across the entire surface area of the container, helping achieve constant results. This can be challenging with various other warmth treatment techniques such as flash pasteurization, however the accurate temperature control that Tunnel pasteurizers provide can make all the distinction for a brewery's procedures.

Environmental Impact

As drink suppliers encounter increasing pressure to decrease their carbon impacts, Tunnel pasteurizers are an important device for maintaining waste to a minimum. The system heats up the container to an exact temperature level for an established duration, getting rid of hazardous microbes without damaging the beverage's physical security or affecting its taste profile.

As an included benefit, Tunnel pasteurization also functions excellent with carbonated beverages-- consisting of the popular craft brews that so many beer lovers enjoy. It assists to expand their life span while protecting those intricate hop notes that customers love a lot.

A firm lately retrofitted their Tunnel pasteurizer to utilize solar power for heating up the fluid, which caused a 35% reduction of water consumption. They have actually also executed a closed-loop drainage treatment plant to further cut their environmental influence also additionally. This demonstrates just how essential lasting techniques are, and just how they're vital to meeting consumer demand and environmental obligation. Stay tuned for future updates on all of the groundbreakings, project starts, ribbon cuttings and buildouts that are happening around the nation!

Securing Top Quality: The Role Of Tunnel Pasteurizers In Beverage Manufacturing

Tunnel pasteurizers are vital for getting rid of putridity microorganisms and regulating pathogenic microbes in drinks like beer, milk, juice and soft drinks. https://phys.org/news/2015-08-brazilian-company-shelf-life-pasteurized.html and afterwards cool the item to remove these microorganisms.

They additionally save energy, water and reduce co2 exhausts aligning production with sustainability targets. Selecting a passage pasteurization system that's engineered by skilled professionals like PRO makes certain precision in the timing and temperature levels made use of in each stage.

Microbiological Control

The control of bacteria in food and drinks is essential to protect against perishing, gastrointestinal disorder, and other adverse influence on the final product. Microbial contaminations can be caused by pathogenic (i.e., disease-causing) organisms or putridity fungis. Techniques for controlling microbial contamination can consist of physical, chemical, or organic techniques. Those that eliminate or suspend bacteria are termed sanitation, sanitation, antisepsis, and sanitization.

Microbial death curves, which depict the logarithmic decrease of living microorganisms after direct exposure to a therapy protocol, are vital devices for establishing the effectiveness of a microbial control approach. The time it considers a protocol to generate a 1-log decrease in the microbial population is called the decimal reduction value, or D-value.

"Elevating Co-Packing Partnerships: The Features and Benefits of Investing in New Tunnel Pasteurizers or Batch Pasteurizers"

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) April 30, 2024

Article by PRO Engineering / Manufacturing Inc.

Click for full article: https://t.co/efrL1fLtBp

PRO Engineering / Manufacturing Inc.

414-362-1500

To ensure exact microbial analysis outcomes, it is very important to keep the example and the test system itself without contamination. Using a microbiological incubator that offers an effective 140 oC decontamination cycle, such as the Thermo Scientific Heratherm Incubator, can assist get rid of cross-contamination in between examples and screening equipment, therefore ensuring that the outcomes of any microbial examinations are valid.

Stability

When it comes to maintaining your drink stable, Tunnel pasteurizers can do a lot of job. These equipments provide both the bottle or can and its contents a warm treatment-- which assists extend shelf life while protecting those specialized components craft breweries enjoy a lot.

In a normal Tunnel pasteurizer, the package and fluid are conveyed via several areas that progressively warm and cool down the product. Each spray head provides water at different temperature levels, and the nozzles are positioned to maximize insurance coverage with a minimum of thermal anxiety.

The timing and temperature of each spray are based on a beverage-specific variety of pasteurization devices (PU) called for to kill any kind of microorganisms in the container. The gradual nature of home heating also lessens carbonation loss in low-carbonated drinks.

Security

Tunnel pasteurizers can be used to warmth deal with a drink also after it has been loaded right into containers and containers. This can assist prolong rack stability for carbonated beverages without compromising their fizz.

The procedure functions by slowly heating up a container with sprays of warm water. The temperature is increased in phases till it gets to the needed pasteurization unit for the drink and after that maintained for the specified period.

When the desired time and temperature level have actually been attained, the beer is cooled down with showers of low-temperature water up until it gets to ambient temperature. This makes certain that all microbes in the beer are killed and it can be securely saved in a sealed container.

Tunnel pasteurizers are designed to ensure that the temperature level is equally dispersed throughout the whole surface of the container, aiding achieve constant results. This can be challenging with other heat therapy methods such as flash pasteurization, however the accurate temperature level control that Tunnel pasteurizers provide can make all the distinction for a brewery's procedures.

Ecological Influence

As drink producers face raising pressure to reduce their carbon impacts, Tunnel pasteurizers are a beneficial device for keeping waste to a minimum. The system heats the container to an accurate temperature for a set duration, removing damaging bacteria without harming the drink's physical security or affecting its taste account.

As an added benefit, Tunnel pasteurization additionally works wonderful with carbonated beverages-- consisting of the preferred craft brews that a lot of beer fans enjoy. It assists to expand their life span while maintaining those complicated jump keeps in mind that customers love so much.

A company recently retrofitted their Tunnel pasteurizer to utilize solar energy for heating the liquid, which resulted in a 35% decrease of water intake. They've additionally applied a closed-loop drainage treatment plant to even more cut their ecological effect even better. This shows how vital lasting practices are, and exactly how they're crucial to satisfying consumer demand and environmental responsibility. Stay tuned for future updates on all of the groundbreakings, job starts, ribbon cuttings and buildouts that are taking place around the country!

Protecting Flavor And Safety And Security: The Value Of Tunnel Pasteurizers In Drink Production

Tunnel pasteurizers are important for getting rid of putridity microorganisms and controlling pathogenic microbes in drinks like beer, milk, juice and sodas. see this page and after that cool down the item to remove these germs.

They likewise conserve power, water and decrease carbon dioxide exhausts lining up production with sustainability targets. Choosing a tunnel pasteurization system that's crafted by experienced professionals like PRO makes certain precision in the timing and temperature level levels utilized in each stage.

Microbiological Control

The control of microorganisms in food and beverages is important to avoid putridity, gastrointestinal disorder, and other adverse influence on the final product. Microbial contaminations can be caused by pathogenic (i.e., disease-causing) microorganisms or wasting fungis. Methods for managing microbial contamination can consist of physical, chemical, or organic approaches. https://www.globenewswire.com/news-release/2021/01/22/2162868/0/en/Growing-With-10-CAGR-Global-Pasteurized-Eggs-Market-Share-Will-Reach-USD-135-Billion-By-2026-Facts-Factors.html that eliminate or suspend bacteria are labelled sanitation, disinfection, antisepsis, and sanitization.

Microbial fatality curves, which illustrate the logarithmic decline of living microbes after direct exposure to a treatment method, are critical tools for establishing the efficiency of a microbial control method. The time it considers a protocol to yield a 1-log decrease in the microbial populace is labelled the decimal reduction value, or D-value.

To ensure accurate microbial evaluation results, it is very important to keep the example and the examination system itself free of contamination. Making use of a microbiological incubator that provides an efficient 140 oC decontamination cycle, such as the Thermo Scientific Heratherm Incubator, can assist eliminate cross-contamination in between samples and screening equipment, hence making certain that the results of any type of microbial tests are valid.

Stability

When it concerns maintaining your beverage stable, Tunnel pasteurizers can do a lot of work. These devices give both the bottle or can and its contents a heat treatment-- which helps prolong service life while protecting those specialty components craft breweries enjoy so much.

In a typical Tunnel pasteurizer, the bundle and liquid are conveyed through several sections that progressively warm and cool down the item. Each spray head provides water at various temperatures, and the nozzles are positioned to take full advantage of insurance coverage with a minimum of thermal anxiety.

The timing and temperature of each spray are based upon a beverage-specific number of pasteurization units (PU) required to kill any type of microorganisms in the container. The gradual nature of home heating likewise decreases carbonation loss in low-carbonated drinks.

Security

Tunnel pasteurizers can be made use of to warm deal with a drink also after it has been packed right into containers and canisters. This can assist extend rack stability for carbonated beverages without sacrificing their fizz.

The process functions by gradually warming a container with sprays of warm water. The temperature level is raised in phases until it reaches the needed pasteurization unit for the drink and after that maintained for the specified period.

When the desired time and temperature have been attained, the beer is cooled down with showers of low-temperature water until it gets to ambient temperature. This makes certain that all bacteria in the beer are eliminated and it can be safely stored in a sealed container.

Tunnel pasteurizers are made to make certain that the temperature level is uniformly distributed across the whole area of the container, aiding accomplish regular outcomes. This can be difficult with various other warm treatment methods such as flash pasteurization, but the precise temperature control that Tunnel pasteurizers provide can make all the difference for a brewery's operations.

Environmental Effect

As beverage makers encounter raising pressure to lower their carbon footprints, Tunnel pasteurizers are an useful tool for keeping waste to a minimum. The system heats the container to a precise temperature for a set period, eliminating dangerous microorganisms without harming the drink's physical security or influencing its taste profile.

As an added advantage, Tunnel pasteurization additionally works excellent with carbonated beverages-- consisting of the preferred craft brews that a lot of beer lovers like. It aids to expand their service life while preserving those complicated jump notes that consumers like so much.

A company just recently retrofitted their Tunnel pasteurizer to utilize solar energy for heating up the fluid, which resulted in a 35% decrease of water usage. They have actually likewise implemented a closed-loop drainage therapy plant to additionally cut their ecological influence also further. This shows how important sustainable practices are, and exactly how they're important to fulfilling consumer demand and environmental obligation. Stay tuned for future updates on every one of the groundbreakings, project starts, bow cuttings and buildouts that are occurring around the nation!

Safeguarding High Quality: The Duty Of Tunnel Pasteurizers In Beverage Production

Tunnel pasteurizers are important for removing wasting microorganisms and controlling pathogenic microorganisms in drinks like beer, milk, juice and soft drinks. They heat and afterwards cool the item to get rid of these germs.

They also save power, water and reduce co2 emissions aligning production with sustainability targets. Selecting a passage pasteurization system that's engineered by seasoned specialists like PRO ensures precision in the timing and temperature degrees used in each stage.

Microbiological Control

The control of microbes in food and beverages is necessary to avoid spoilage, food poisoning, and other unfavorable impacts on the end product. https://www.foodsafetynews.com/2011/03/drinking-raw-milk-more-details-on-the-risks/ can be caused by pathogenic (i.e., disease-causing) microorganisms or wasting fungis. Techniques for controlling microbial contamination can consist of physical, chemical, or organic methods. Those that eliminate or suspend microbes are described sanitation, disinfection, antisepsis, and sanitization.

please click the following post , which show the logarithmic decline of living microbes after exposure to a therapy protocol, are crucial tools for figuring out the performance of a microbial control strategy. The moment it considers a method to yield a 1-log reduction in the microbial populace is termed the decimal reduction value, or D-value.

"FINANCING AND LEASING OPTIONS FOR BEVERAGE MANUFACTURING: A PATH TO BOOSTING PRODUCTION AND PROFITS WITH TUNNEL AND BATCH PASTEURIZERS WITH PRO ENGINEERING / MANUFACTURING INC."

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) January 16, 2024

Click for article: https://t.co/OHtseWmVZL

PRO Engineering / Manufacturing Inc.

414-362-1500

To ensure precise microbial analysis outcomes, it is necessary to keep the sample and the examination system itself without contamination. Making use of a microbiological incubator that provides an efficient 140 oC decontamination cycle, such as the Thermo Scientific Heratherm Incubator, can aid eliminate cross-contamination between examples and testing equipment, therefore making certain that the outcomes of any microbial examinations are valid.

Security

When it comes to keeping your drink secure, Tunnel pasteurizers can do a great deal of job. These equipments provide both the bottle or can and its contents a warmth therapy-- which assists expand shelf life while preserving those specialty active ingredients craft breweries love so much.

In a normal Tunnel pasteurizer, the package and liquid are conveyed via a number of sections that progressively warm and cool down the product. Each spray head supplies water at various temperature levels, and the nozzles are placed to make the most of protection with a minimum of thermal anxiety.

The timing and temperature of each spray are based on a beverage-specific number of pasteurization devices (PU) required to eliminate any type of bacteria in the container. The progressive nature of heating additionally minimizes carbonation loss in low-carbonated drinks.

Safety and security

Tunnel pasteurizers can be made use of to heat treat a beverage even after it has been packed into bottles and containers. This can help extend rack security for carbonated beverages without compromising their fizz.

The process functions by slowly heating up a container with sprays of warm water. The temperature is increased in stages till it gets to the called for pasteurization system for the beverage and then preserved for the specified duration.

Once the wanted time and temperature have actually been achieved, the beer is cooled with showers of low-temperature water till it gets to ambient temperature level. This guarantees that all bacteria in the beer are eliminated and it can be safely stored in a secured container.

Tunnel pasteurizers are created to make sure that the temperature is uniformly dispersed across the whole surface area of the container, helping attain regular outcomes. This can be challenging with various other warmth treatment techniques such as flash pasteurization, but the exact temperature level control that Tunnel pasteurizers give can make all the difference for a brewery's procedures.

Environmental Effect

As drink producers encounter boosting stress to decrease their carbon footprints, Tunnel pasteurizers are a beneficial device for maintaining waste to a minimum. The system heats the container to an accurate temperature for an established period, removing hazardous microorganisms without harming the drink's physical stability or influencing its taste profile.

As an added benefit, Tunnel pasteurization also works terrific with carbonated beverages-- consisting of the prominent craft makes that so many beer lovers love. It assists to expand their service life while maintaining those complicated jump keeps in mind that customers enjoy so much.

A business just recently retrofitted their Tunnel pasteurizer to make use of solar power for warming the fluid, which resulted in a 35% reduction of water consumption. They have actually likewise implemented a closed-loop waste water treatment plant to better cut their environmental effect even better. This shows exactly how essential lasting techniques are, and just how they're important to fulfilling consumer demand and environmental duty. Remain tuned for future updates on every one of the groundbreakings, task begins, ribbon cuttings and buildouts that are happening around the country!

Protecting Quality: The Significance Of Tunnel Pasteurizers In Beverage Production

Tunnel pasteurizers are crucial for getting rid of putridity microorganisms and controlling pathogenic microorganisms in beverages like beer, milk, juice and sodas. They warmth and then cool the item to remove these microbes.

They additionally conserve power, water and lower co2 exhausts lining up production with sustainability targets. Picking a passage pasteurization system that's crafted by skilled specialists like PRO makes certain accuracy in the timing and temperature degrees made use of in each phase.

Microbiological Control

The control of microorganisms in food and beverages is essential to avoid wasting, food poisoning, and other negative effect on the final product. Microbial contaminations can be brought on by pathogenic (i.e., disease-causing) microorganisms or putridity fungi. https://newatlas.com/naturo-heat-free-milk-processing-long-shelf-life/59520/ for regulating microbial contamination can consist of physical, chemical, or biological methods. Those that eliminate or inactivate microbes are called sanitation, sanitation, antisepsis, and sanitization.

Microbial death curves, which portray the logarithmic decline of living microbes after exposure to a therapy procedure, are important devices for establishing the efficiency of a microbial control approach. The time it takes for a procedure to yield a 1-log decrease in the microbial populace is described the decimal reduction value, or D-value.

To make certain precise microbial analysis outcomes, it is necessary to keep the example and the examination system itself without contamination. Making use of a microbiological incubator that supplies an efficient 140 oC decontamination cycle, such as the Thermo Scientific Heratherm Incubator, can assist eliminate cross-contamination between examples and testing equipment, therefore making sure that the outcomes of any type of microbial tests are valid.

Security

When it concerns keeping your beverage secure, Tunnel pasteurizers can do a lot of job. These devices give both the bottle or can and its materials a warmth treatment-- which assists extend shelf life while preserving those specialized ingredients craft breweries enjoy so much.

In a typical Tunnel pasteurizer, the package and liquid are communicated via numerous sections that slowly warm and cool the item. Each spray head provides water at various temperature levels, and the nozzles are positioned to make the most of insurance coverage with a minimum of thermal anxiety.

why not look here and temperature of each spray are based on a beverage-specific number of pasteurization devices (PU) required to kill any bacteria in the container. The steady nature of heating also minimizes carbonation loss in low-carbonated drinks.

Safety

Tunnel pasteurizers can be made use of to warmth deal with a drink also after it has been packed right into containers and cans. This can assist lengthen shelf stability for carbonated beverages without compromising their fizz.

The process works by progressively heating a container with sprays of hot water. The temperature level is elevated in phases till it reaches the needed pasteurization system for the beverage and afterwards preserved for the defined period.

When the wanted time and temperature have actually been attained, the beer is cooled with showers of low-temperature water until it gets to ambient temperature. This makes certain that all bacteria in the beer are killed and it can be safely saved in a secured container.

Tunnel pasteurizers are designed to make sure that the temperature level is evenly dispersed throughout the entire area of the container, aiding accomplish consistent results. This can be difficult with other warm treatment techniques such as flash pasteurization, however the exact temperature control that Tunnel pasteurizers give can make all the difference for a brewery's operations.

Environmental Impact

As beverage suppliers encounter enhancing pressure to reduce their carbon impacts, Tunnel pasteurizers are a beneficial tool for keeping waste to a minimum. The system heats up the container to an exact temperature for an established period, removing unsafe bacteria without harming the drink's physical stability or influencing its flavor account.

As an included advantage, Tunnel pasteurization likewise functions wonderful with carbonated beverages-- consisting of the prominent craft brews that so many beer enthusiasts enjoy. It assists to prolong their life span while preserving those complicated jump notes that customers love a lot.

A company just recently retrofitted their Tunnel pasteurizer to use solar power for heating the fluid, which led to a 35% reduction of water usage. They have actually likewise executed a closed-loop drainage therapy plant to better cut their environmental impact even additionally. This shows exactly how essential sustainable techniques are, and how they're important to meeting consumer demand and ecological responsibility. Stay tuned for future updates on all of the groundbreakings, project begins, ribbon cuttings and buildouts that are occurring around the country!

Every Little Thing You Need To Know About Tunnel Pasteurizers: Their Performance And The Reasons Why They Are Vital

Tunnel pasteurizers help prolong beer rack stability and maintain tastes standing out without the aid of chemicals. They do this while eliminating microorganisms and inactivating yeast and mold and mildews.

The bottled product, either bottles or cans, goes into the Tunnel and experiences a pre-heating area where it gets sprayed with hot water. From there, it's slowly brought to the wanted pasteurization temperature level and after that cooled.

Just how They Function

Tunnel pasteurizers make use of a conveyor system to move products with a temperature-controlled Tunnel. As the beer containers and containers relocate via the Tunnel, they are constantly splashed with warm water, which progressively raises their temperature levels up until they reach the desired pasteurization level. Then, the containers are held at that temperature level for a collection amount of time and then cooled once more.

After the pasteurization procedure is total, the beer cans and containers are transferred to a cooling Tunnel where their temperature levels are reduced incrementally up until they reach space temperature again. This is done to avoid the drinks from experiencing a sudden cold shock, which could change their flavor profiles.

While Tunnel pasteurizers can be utilized by both big and tiny breweries, it is very important that the ideal one is picked for your brewery. It's finest to select a system designed and constructed by relied on, experienced market professionals. Click To See More will make certain that your system can take care of the certain temperature degrees and timing required for carbonated beverages while likewise comparing with your assembly line's circulation.

Why They're Vital

Tunnel pasteurizers supply an effective option to extending service life without compromising item high quality. While flash pasteurizers can just target the liquid inside the bundle, Tunnel machines warmth both the container and the materials - suggesting they can extend a beer's rack security without impacting its complex jump notes.

Furthermore, tunnels are wonderful for carbonated drinks as well - no require to fret about the heat damaging those carbonated bubbles. Especially for craft breweries, Tunnel pasteurization is an indispensable device to guarantee their items' lasting rack security-- all without jeopardizing the delicious preference that consumers love.

Besides being effective, Tunnel pasteurizers are also flexible and personalized. Temperature levels in the various zones can be optimized to lower power usage and keep optimum pasteurization levels. This is attained by readjusting the heating & cooling temperature levels to match the demands of the certain drink being treated (2 ). Additionally, the spraying nozzles can likewise be tailored to fit the bottle size and setup.

What You Required to Know

Simply put, Tunnel pasteurizers are a valuable tool for breweries and various other drink manufacturers wanting to expand their drinks' shelf life. They can be used to exterminate any virus or microorganisms in the fluid and its packaging. This will assist to prevent the drinks from ruining or wearing away before they get to customers.

A tunnel pasteurizer is a maker that takes the already-bottled product and passes it with numerous temperature zones with raising heat, till it gets to the desired pasteurization temperature level. Then it is cooled.

The heating & cooling of the containers in a tunnel pasteurizer is performed making use of a collection of spray nozzles. The accurate positioning of these nozzles optimizes the effect and minimizes the mixing of water between various areas. They are also maximized to minimize power intake. Additionally, click to read for carbonated beverages - so they can shield your fizzy beers from over-carbonation and guarantee their durability. This is especially essential for craft breweries and other beverage producers that wish to maintain their customers happy.

The Final Words

Tunnel pasteurizers are a large piece of machinery which contains an enclosed conveyor belt system where the bottles or canisters move with areas that each have a particular temperature level and dwell time. Once the items are splashed or immersed in hot water and held at that temperature for the appropriate amount of time, they're then promptly cooled off and permitted to make their escape of the device.

Tunnel pasteurization is a great way to prolong the service life of your beer and assistance stop dangerous impurities from ruining your beverage. However, because it warms up the liquid as long, a number of the qualities that provide your beers their scrumptious flavor and scent can additionally get ruined while doing so.

One option to Tunnel pasteurization is flash pasteurization, which heats up the beer for a shorter time period and helps preserve those specialty ingredients you worked so tough to source for your beers. While flash pasteurization does cost more ahead of time, it can conserve you cash in the long run by protecting against pricey food and drink remembers.

Leading 7 Security Attributes To Seek In Skid Steer Devices

When it comes to running skid steer equipment, safety and security should be your leading priority. You might be believing, 'However aren't skid steer equipments already secure?' While they are made with several built-in safety functions, it is very important to be familiar with the leading 7 safety and security features you need to search for.

By comprehending these attributes and guaranteeing they are present in the tools you utilize, you can greatly decrease the threat of mishaps and injuries. From Rollover Defense Solution (ROPS) to rearview and sideview mirrors, these features are created to maintain you secure and safeguarded while operating the tools.

So, allow's dive in and explore the top 7 security functions you must never overlook when it pertains to skid steer tools.

## Rollover Defense System (ROPS).

Try to find a skid guide devices with the Rollover Protection System (ROPS) to ensure your safety. ROPS is a critical security feature that safeguards you in case of a rollover accident. It contains a strengthened framework, such as a roll cage or a protective canopy, that surrounds the driver's area.

In case of a rollover, ROPS provides a protective area, preventing the driver from being crushed or harmed. This safety and security attribute is particularly crucial when working on uneven terrain or in locations with a high threat of tipping over.

When picking a skid guide tools, see to it it's equipped with ROPS to decrease the danger of significant injuries and even deaths. Your security must always be the top concern.

## Overhead Guard.

One essential security function to take into consideration when selecting skid guide equipment is the overhanging guard's toughness.

The above guard works as a safety framework that shields the driver from dropping objects and particles.

It's important to make certain that the overhanging guard is created with high-quality products and designed to endure possible influences.

A solid expenses guard not just protects against injuries but additionally improves the general safety and security of the operator.

When running in dangerous atmospheres, such as building and construction sites or farming setups, the danger of objects dropping from above is a consistent worry.

## Back-up Alarm system.

Ensure to have a backup alarm installed on your skid steer equipment for added safety and security. A back-up alarm is a crucial safety function that notifies people around when the automobile is moving in opposite. This alarm system produces a loud, distinctive audio that acts as a warning signal.

By having a backup alarm, you can significantly lower the threat of accidents and stop collisions with pedestrians or various other cars. It helps to create understanding and ensure that everybody stays alert and careful when the skid steer tools is supporting.

When running in active worksites or constrained areas, where exposure may be restricted, a backup alarm system ends up being a lot more necessary in preventing mishaps and keeping a secure workplace.

## Seat Belt.

Make certain that you attach your seat belt appropriately for optimum safety when running skid guide tools.

The seat belt is an essential safety attribute that assists to shield you in case of an accident or abrupt quit. By wearing your seat belt, you can prevent ejection from the device, decreasing the threat of significant injury or even death.

Ensure to readjust the seat belt to fit well across your lap and shoulder, making sure that it isn't twisted or as well loose.

It's important to use your seat belt in all times, even if you're only running the skid steer for a short period.

## Driver Existence System (OPS).

Are https://www.lawnandlandscape.com/article/ll-071918-boss-snow-plow-new-plows-accessories/ of the value of the Driver Presence System (OPS) when operating skid steer tools?

The OPS is a crucial security attribute that helps avoid accidents and injuries. It works by needing the driver to be seated in the maker and have their seat belt secured before the equipment can be run.

If the driver leaves the seat or eliminates their seat belt, the OPS will instantly quit the engine and the hydraulic system, bringing the device to a halt. This function makes sure that the skid guide tools stays fixed and stops it from being mistakenly run by unauthorized individuals or in dangerous conditions.

The OPS supplies an extra layer of protection and helps keep the safety of both the driver and those working around the tools.

## Accessory Hydraulic Lockout.

One vital security feature to consider when looking for skid steer equipment is the supporting hydraulic lockout. This function is designed to avoid unintentional movement of the hydraulic functions, offering an added layer of defense for both the operator and those around them.

By shutting out the supporting hydraulics, it ensures that attachments or executes can't be triggered accidentally, lowering the threat of injury or damages. This function is specifically valuable when doing upkeep or repair services on the devices, as it stops any kind of unforeseen activity that can lead to accidents.

The auxiliary hydraulic lockout adds an extra level of safety and comfort, allowing operators to function confidently and efficiently, understanding that the equipment's hydraulic functions are safely secured when not in use.

## Rearview and Sideview Mirrors.

To boost safety and security, consider equipping your skid steer tools with rearview and sideview mirrors. These mirrors supply essential visibility, enabling you to see what's taking place behind and next to your device. With rearview mirrors, you can conveniently keep track of tasks and possible threats in your blind spot, making certain the safety and security of both on your own and others on the worksite.

Sideview mirrors, on the other hand, offer you a bigger line of vision, allowing you to browse limited rooms and stay clear of collisions with things or various other tools. By having these mirrors set up, you can greatly lower the threats connected with operating a skid guide.

## Final thought.

So, when it concerns skid steer devices, security needs to always be your leading priority.

The top 7 security functions talked about in this write-up, including Rollover Protection System, Seat Belt, and Driver Visibility System, are vital for stopping accidents and guaranteeing the health of operators.

By investing in skid steer equipment with these safety features, you can have comfort understanding that you're taking the required steps to protect yourself and your employees.

Do not await a disaster to strike, make safety a top priority today!

Crucial Tips For Operating Skid Steer Equipment Securely

Are you ready to grasp the art of operating skid steer equipment securely? Look no further! This guide is loaded with crucial tips to help you browse through any kind of job site with confidence.

From tools inspection and maintenance to correct operator training, we've got you covered. Safety should constantly be your top concern, and by adhering to these pointers, you can make sure a smooth and accident-free operation.

So, twist up, put on your safety and security equipment, and get ready to take control of your skid steer tools like a pro. With these suggestions in your tool kit, you'll be running easily and effectiveness quickly.

Let's get started!

Tools Examination and Maintenance

Exactly how typically should you inspect and keep your skid steer equipment?

It's important to evaluate and preserve your skid steer devices regularly to ensure its risk-free and effective operation. By carrying out routine examinations, you can recognize any kind of potential problems before they escalate right into significant problems.

It's suggested to perform a thorough assessment before each use, looking for any indications of wear and tear, loosened or broken components, and liquid leaks.

In addition, regular upkeep should be carried out according to the supplier's guidelines, including jobs such as transforming filters, oiling moving components, and inspecting the hydraulic system.

Appropriate Driver Training

To operate skid steer tools securely, you require correct training. Skid guide loaders are effective machines that require ability and proficiency to operate effectively.

In order to ensure your safety and security and the safety of those around you, it's important to receive detailed training on just how to utilize these equipments correctly. Appropriate driver training will educate you the fundamentals of operating skid steer equipment, consisting of comprehending the machine's controls, maneuverability, and security functions.

In addition, training will certainly cover subjects such as lots capacity, security, and correct attachment use. By obtaining the necessary training, you'll be geared up with the expertise and abilities to run skid steer devices securely and successfully, lessening the risk of crashes and injuries on the job website.

Safe Operating Practices

Exercise proper security methods when operating skid guide devices. Safety and security should always be your top priority to prevent crashes and injuries.

Initially, make certain to wear appropriate personal safety equipment, such as a hard hat, shatterproof glass, and steel-toed boots.

Prior to beginning the devices, check it thoroughly for any damages or malfunctioning components. Clear the workplace of any possible risks, such as particles or challenges.

Keep bystanders at a safe distance to avoid mishaps. Always operate the skid steer at a secure speed and avoid sudden activities or sharp turns.

Beware when operating unequal surface or inclines. Lastly, never leave the equipment ignored or running.

Final thought

So bear in mind, when operating skid steer equipment, always focus on security.

Regularly evaluate and maintain the devices to avoid any kind of potential dangers.

Guarantee that you and your operators are correctly educated to manage the machinery.

And read this , practice risk-free operating techniques to secure yourself and others around you.

Can you afford to take any kind of dangers when it pertains to the safety and security of your group?

Tunnel Pasteurizers For Beer & Drink Makers Are Effective Means To Sterilize The Products

The beer as well as beverage sector needs a straightforward, reliable as well as economical method of sterilizing their items. Both Tunnel and also flash pasteurization are effective methods to do this.

With https://www.stuff.co.nz/life-style/food-wine/food-news/102123278/its-almost-impossible-for-raw-milk-to-be-free-of-faeces-bacteria--expert , liquid-filled containers or bottles are sprayed with hot water in a sanitary stainless-steel Tunnel. While doing so, microbes are damaged and also the product's temperature is raised in phases up until it reaches its optimum desired degree.

Set Pasteurizers

Beer & Beverage Makers need pasteurizers to eliminate unsafe bacteria as well as yeast that can damage product as well as make it unsafe for intake. They likewise need the capacity to securely process high-speed line prices that can be difficult to by hand handle.

Set pasteurizers heat sets of milk or various other milk items in a container, making use of either circulating water or steam to hold the product at a preferred temperature. The product is held for a collection amount of time.

GEA can offer a wide range of equipment for these processes. These consist of HTST and also Ultra High Temperature (UHT) pasteurizers.

GEA's pasteurizers are designed to heat every bit of the item to a specific temperature. This ensures that all bacteria and also pathogens are killed and the item is secure to consume.

Constant Pasteurizers

A continuous pasteurizer can be used to produce a wide range of beverages such as milk, yogurt as well as cheese. It is an extra reliable as well as cost effective method of creating these products than set pasteurization.

These systems utilize water at the ideal temperature level to heat, hold as well as cool down a beverage in a secured container. They are ideal for high-volume throughput as well as can lower post-processing contamination.

The process is called Greater Temperature level Shorter Time (HTST) pasteurization as well as is a common method of creating milk products. It can likewise be adjusted for use in the beer and also other food markets.

Circulation Pasteurizers

Circulation Pasteurizers for Beer & Beverage Makers are designed to warm and cool a range of liquids. They use a series of spray nozzles inside the Tunnel to spray water at different temperature levels and to make certain optimum warm exchange in between the water and your item.

These equipments likewise use a water conserving system that gathers excess water throughout operation to decrease the amount of power needed for re-cooling as well as warming. This saves power and water while preserving high sanitary criteria.

This sort of equipment is ideal for a wide variety of drink products such as milk, white wine, fruit juice and various other drinks. They are suitable for continual pasteurization or flash pasteurization with automatic control of temperature and quantity conversion speed, and also can reheating as much as 125 degrees Celsius.

Depending on the application, this kind of machine is offered with optional suction boxes to house conveniently obtainable inlet screens that keep debris out of the pump device. It is likewise possible to add an HMI/PLC to supply easy machine control.

Hermis Pasteurizers

The Hermis Tunnel pasteurizer is a maker made to enhance the biological security of beer, kvass and also various other beverages by warming them to a predetermined temperature level. Its ability to warm and also cool rapidly and effectively boosts their life span.

Hermis Tunnel pasteurizers come in a selection of sizes to fit your brewery's production needs. They are readily available in automated as well as semi-automatic modes.

They are additionally equipped with several of one of the most sophisticated modern technology on the market, including a re-pasteurization protection system, circulation meter and temperature level recorder. Additionally, a disinfectant dosing system as well as container clothes dryer are offered on request.

The very best part is that every one of these attributes are integrated in a system developed to be hygienic and also very easy to keep. The royal prince control software takes care of fresh water in a new and also ingenious means, leading to minimized water and also heavy steam usage even in the most requiring of applications. It maximizes the PU build-up for any kind of beginning as well as stop series, achieving the drink trifecta of product safety and security, item high quality and reliable procedure.

Continue Reading To Get More Information Information About Tunnel Pasteurizers For Beer & Beverage Makers

Tunnel Pasteurizers make use of heat to safely refine food and also various other items. The process uses different zones where water is splashed in order to warm up and also cool down the product being pasteurized. In some machines, the temperature level of the water is checked, which ensures the process is working correctly. Tunnel Pasteurizers can be made use of in a large range of applications.

Tunnel Pasteurizers are utilized to securely and also regularly pasteurize packaged drinks, such as beer and wine. These machines make use of a conveyor to relocate the packages through a long, slim Tunnel. The Tunnel is normally 15 to 30 meters long and also is consisted of several temperature zones. The initial area is the home heating area, and the 2nd area is the holding or cooling down zone. During the process, water is splashed onto the cans as well as containers.

Tunnel Pasteurizers can produce items with raised shelf life by shutting off enzymes as well as microorganisms. Modern Tunnel pasteurizers conserve energy by using innovative modern technology. The layout of these machines enables a modular installation, which helps reduce setup expenses. They additionally feature continuous belts made of polypropylene or stainless-steel. The home heating as well as cooling procedure is controlled by a PLC. If you require a pasteurizer for your production line, you can contact Diversey to get more information concerning what is available in your area.

The Tunnel Pasteurizer display is a software as well as hardware system that monitors the pasteurization process and controls the water splashing inside the Tunnel. It likewise has an integrated temperature sensor that measures the temperature and time of each individual area. This data is important in calculating the pasteurisation units. Tunnel Pasteurizers are an excellent choice for pasteurizing lots of products. So, consider them if you are trying to find a top quality, reliable pasteurizer.

Tunnel Pasteurizers are effective devices that get rid of recurring germs from food as well as drink items. The HT205 mini Tunnel pasteurizer supplies adjustable parameters that allow the driver to duplicate a large range of full-blown production circumstances. It additionally conserves water and power, which are both essential components for a production line.

Tunnel Pasteurizers are typically made from stainless steel, and they are available in different sizes as well as measurements. This enables them to be customized to the specific food types as well as procedures that you generate. Besides being easy to use, they likewise do not ruin the taste or structure of the product. They likewise come with automatic-stop systems that protect against overpasteurization.

There is a place for pasteurization in little breweries too. The procedure can preserve the taste of beer even if it is generated in a tiny scale brewery. Small breweries are increasingly recognizing the worth of pasteurization as well as are applying the innovation to make craft brewing a success.

The Tunnel pasteurizer can warm milk at a rate of 363 kgs per hr. In ninety percent of situations, the milk is cooled back down to 4.5 degC. Check This Out improves the pressure on milk leaving the regrowth area, resulting in a pressure differential of 41.4 kPa over the feed or raw side of the regeneration device. The MST sterilized milk has a service life of approximately 60 days at 4 degC, as well as the complete decrease of germs is more than 5 log cycles.

Tunnel Pasteurizers Are Machines That Are Utilized To Sanitize Packaged Items And Also Expand Their Service Life

These makers have several areas that each include their very own water spray system as well as blood circulation pump, in addition to a screen/filter box. When these systems malfunction, they can adversely affect the process, item top quality, performance, and also complete expense of possession.

Tunnel Pasteurizers function by distributing hot water under the pasteurization belt. The water might be sent to the discharge conveyor or to a sump. The sump lies under the pasteurization belt. As bottles overlook the pasteurization belt, some of them might damage. Broken containers are accumulated in the sump. Or else, click here to investigate continue along the conveyor. The sump is designed to have water tight ports that enable maintenance workers access to the water.

“WHAT IS THE BEST PASTEURIZATION METHOD FOR BEER AND BEVERAGES?”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) January 17, 2023

Article Release for Brewmasters & Beverage Makers, sponsored by PRO Engineering / Manufacturing Inc.

Click for full article:https://t.co/O633OluiN1

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/r2lM9FPwKp

Tunnel Pasteurizers are perfect for a selection of applications. For example, Tunnel pasteurizers can be utilized for developing beer, tinned mixed drinks, and also various other items that have a closed container. These devices can be customized to suit the manufacturing area of a firm. They can be found in a variety of dimensions, depending on the quantity and also temperature level needed for the products. If you require to treat greater than one item, you can install a dual-story device.

Tunnel Pasteurizers can be an economical method to sterilize bottled beverages. They can also be extremely power efficient. They utilize sophisticated innovation to eliminate bacteria as well as enzymes that create microorganisms as well as other unsafe substances. They also have a modular design for lowered installation costs. Single-deck tunnels can vary from 5 to 500 m2. Constant belts are offered in stainless-steel as well as polypropylene.

related webpage can refine a wide range of items, such as juices as well as jams. It can be furnished with an air conditioning system in the control cupboard. The temperature level and also time utilized throughout pasteurization vary according to the type of item. A a great deal of companies use these gadgets to pasteurize their products. They are likewise simple to preserve and solution.

Tunnel Pasteurizers are reliable machines that kill microorganisms, stop fermentation, and also supply shelf security to bottled products. These machines undergo significant temperatures as well as caustic cleansing chemicals. They can likewise be harmed by damaged bottles. At PRO Engineering/Manufacturing, we have experience creating and also constructing Tunnel pasteurizers for food as well as beverage companies.

Tunnel Pasteurizers are different from tubular, plate, as well as mass pasteurizers in numerous methods. The latter has a recording device that tape-records details of the procedure. This makes it a much more efficient and accurate means to heat as well as awesome bundles. Tunnel Pasteurizers are usually cheaper than mass pasteurizers as well as are a lot more power effective. Nevertheless, the temperatures of the Tunnel pasteurizer can differ from time to time.

Depending upon the water chemistry of the Tunnel pasteurizer system, containers and also canisters can experience different high quality issues. As an example, unlacquered canisters and bottles can establish rust places and discoloration. Unlacquered canisters may likewise experience fading of decorations. Those that use these systems need to check their neighborhood range of items.

Tunnel Pasteurizers can be an effective way to sterilize milk. This innovation also allows manufacturers to extend the life span of their products. Also small-scale breweries can benefit from pasteurization. As an example, if a brewery has no refrigeration equipment, they can utilize Tunnel pasteurizers to sterilize their items. An effective commercial plant might have the ability to process as much as 240,000 L of milk per hr.

This Post Reviews The Benefits Of Powder Coating

Using Powder Coating on a car will provide the auto a beautiful, glossy finish. simply click the next site of Coating is applied as a dry powder and is then cured with heat or ultraviolet light.

Electrostatic spray deposition technique

Whether you're seeking a high-performance Coating or a cost-efficient option to liquid paints, you can discover an electrostatic spray deposition approach that suits your needs. The technique functions by using a layer of powder to a steel substrate. It can be made use of to layer pipes, for instance, for enhanced durability.

Contrasted to fluid applications, electrostatic spray deposition is more sturdy and also a lot more cost-efficient. While standard damp paint can leave you with an irregular coating, this approach leaves your components smooth and glossy.

This process needs the use of a specialized spray gun. It likewise makes use of compressed air to press the powder via the weapon and also out of the nozzle. This air moves the powder along at a high price and also atomizes the powder. It is additionally a terrific means to avoid clumping.

Unlike typical damp paint, powder Coating additionally does not require a solvent. It likewise offers a variety of coatings as well as appearances. This method can be utilized on a selection of substratums, consisting of non-metallic products such as plastics.

Fluidized bed system

Numerous industries rely on fluidized bed powder Coating to layer metal parts. This Coating gives a thick layer of protection against wear and corrosion. The process includes warming the part as well as dipping it into the fluidized bed. The part after that transfers to a reduced temperature stove for treating.

During the process, a driver has to pay attention to the rate of the line and the temperature of the component. This is required to preserve consistent application of powder. It is also crucial to note that the Coating density is dependent on the temperature of the part as well as the duration it invests in the fluidized bed.

Electrostatic fluidized beds are especially matched for constant Coating of little easy arrangement components. This type of Coating requires high dielectric toughness as well as film thickness control.

Electrostatic fluidized beds are also suitable to constant Coating of cable screens. The electric area strength of these finishes is reduced. This makes them more suitable for finishes that require much less air circulation and also better performance in Faraday cages.

Variants between fluid paint as well as powder coat

Despite the distinctions in between liquid paint as well as powder coat, both finishing methods are used by sectors for comparable applications. Both are used to secure metal surface areas from oxygen and flying particles.

The distinctions in between both are mainly related to the application methods. Both approaches can leave smooth surfaces on a surface area, yet there are numerous benefits to picking one over the other.

Powder Coating is extra long lasting and also brings a reduced carbon footprint than fluid paint. It also provides a variety of wellness benefits. It is additionally easier to use. Powder finishings are normally without unstable organic compounds (VOCs) and also can produce thicker layers than fluid coatings.

Powder finishings also use a variety of specialized impacts. Some of these results consist of pearlescents, flip-flops, and dormant pigments.

The primary difference between powder and fluid paint is that powder Coating is applied as a completely dry powder, which means that the shade does not fade. The shade of a powder layer will certainly vary depending on the polymers utilized to make it.

Longevity

Relying on the kind of Coating, powder Coating can last anywhere from fifteen to twenty years. It is utilized on a selection of surface areas including metal, fiberglass, and also some plastics. This long lasting finish safeguards against the climate and also chemicals, that makes it especially valuable in the building market.

https://squareblogs.net/gina41tona/lets-goes-over-the-benefits-of-powder-coating-in-this-post supplies a high-quality surface that is resistant to deterioration. The Coating will certainly not chip or peel, and also the shades will remain brilliant and lively for longer than conventional damp paint. It is additionally long lasting and also will certainly stand up to bumps as well as bending without delaminating.

https://www.cosmopolitan.com/style-beauty/beauty/g31817042/best-dip-powder-nail-kit/ is less unsafe to the setting than conventional fluid paint finishing. It generates very little hazardous waste and also releases minimal amounts of unpredictable organic substances (VOCs) right into the atmosphere.

Powder Coating can be utilized to paint house items, in addition to outside things like furniture. It can also be made use of to shield construction equipment as well as machinery. It is an economical surface that is durable and also will last for many years to come.

The Benefits And Downsides Of Powder Coating

Unlike traditional liquid paint, powder Coating is applied as a free-flowing, dry powder, which is then healed with heat or ultraviolet light. In addition, powder Coating is usually used electrostatically.

Electrostatic spray gun

Utilizing an Electrostatic spray gun for powder Coating is a wonderful means to create an excellent quality surface on your work. This method is made use of to develop a resilient coating that can withstand rust as well as chipping.

The electrostatic spraying method utilizes compressed air to carry the powder to the work surface. The weapon produces a high-voltage electrostatic field that attracts the powder fragments to the metal. This produces a layer that complies with the steel in a thick, even layer.

One of the most evident advantage of an Electrostatic spray gun is boosted transfer effectiveness. This allows for a more consistent coat, less overspray, and much less waste.

There are several setups to select from on your Electrostatic spray gun. Choosing the right ones can improve your powder Coating performance. There are a few crucial setups to be familiar with.

The kilovolt (kV) is the system of procedure for the electrostatic powder weapon cost. The greater the voltage, the more dimples you will see in your Coating. It is best to set the voltage reduced to achieve the most effective outcomes.

Polymer resin systems

Numerous polymer resin systems are made use of in the manufacture of powder Coating. https://www.coatingsworld.com/issues/2022-07-01/view_breaking-news/hempel-launches-new-fast-drying-cui-coating/ are designed to offer resilient layers with a variety of shades and textures. They are additionally an eco-friendly alternative to fluid paints.

Normal powder finishings are developed with a blend of pigments and also ingredients. These ingredients are thawed, blended, and then ground into a powder. They are then put on the substratum making use of electrostatic spray deposition. The powder is after that cured in a healing stove.